Supercritical CO₂ Sterilization: An Eco-Friendly and Sustainable Alternative for Medical Devices

Medical devices regulation

As environmental challenges grow within the medical device industry, supercritical CO₂ sterilization emerges as an innovative, eco-friendly solution. While established methods like ethylene oxide (EtO) are recognized for their effectiveness, they also carry risks of toxic residues and pollutant emissions. In contrast, supercritical CO₂ provides a low-impact alternative that is safer for both users and patients.

What is Supercritical CO₂? An Eco-Friendly and Effective Technology

Supercritical CO₂ sterilization uses carbon dioxide heated and pressurized to a “supercritical” state. In this state, CO₂ combines both liquid and gas properties, allowing it to deeply penetrate materials for optimal sterilization. Unlike chemicals like EtO, which generate polluting waste, the CO₂ used in this process is often reclaimed and reused in a closed-loop system, reducing the carbon footprint of the process.

How Supercritical CO₂ Reduces Environmental Impact

One of the primary benefits of supercritical CO₂ sterilization is its ability to minimize toxic residues and polluting emissions. The CO₂, often sourced from other industries, is reused without needing additional production, making it an environmentally responsible process. This recycling approach helps reduce the carbon footprint of the process, aligning with the European Union’s greenhouse gas reduction goals.

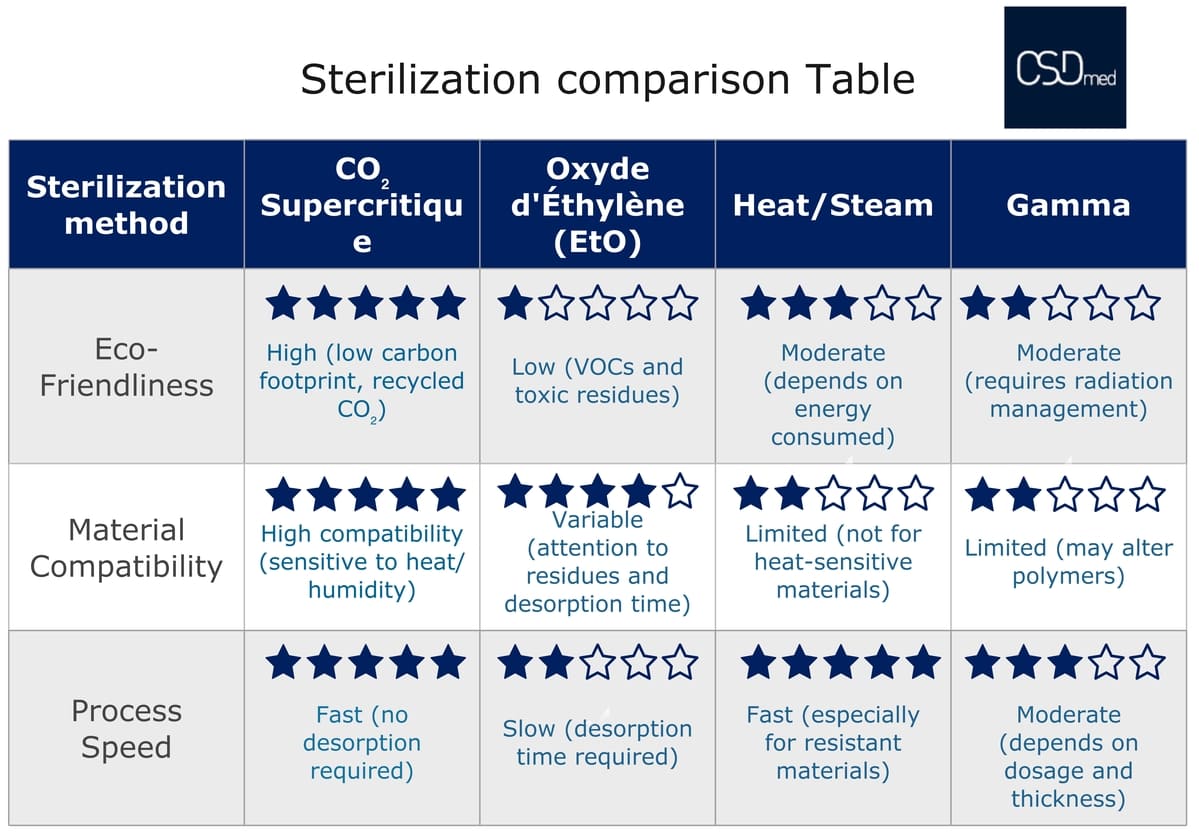

Comparing Medical Device Sterilization Methods

1. Limitations of Ethylene Oxide (EtO)

Sterilization Ethylene oxide (EtO) sterilization is effective, but it generates chemical residues that require a lengthy desorption period to ensure user safety. Additionally, EtO poses environmental risks due to volatile organic compound (VOC) emissions, which contribute to air pollution.

2. Heat and Steam Sterilization

Heat or steam sterilization is common but imposes constraints on materials sensitive to temperature and moisture, limiting its application for certain medical devices.

3. Gamma Sterilization

Gamma sterilization uses gamma rays to kill microorganisms on medical devices without requiring heat or chemicals. Although effective, this method can cause changes in polymer materials, altering their mechanical properties and reducing their lifespan. It also requires strict safety protocols due to radiation and involves costly facilities.

In comparison, supercritical CO₂ sterilization can treat a wider range of materials, including thermolabile and moisture-sensitive devices, while being non-toxic and residue-free.

Benefits of Supercritical CO₂ for Sensitive Medical Devices

Beyond its low environmental impact, supercritical CO₂ sterilization is ideal for devices sensitive to heat and moisture. It allows fragile materials to be sterilized without risking degradation, preserving their original properties. By adopting this technology, manufacturers can meet safety and quality requirements while reducing their ecological footprint.

A Faster, Standards-Compliant Process

The supercritical CO₂ sterilization process is faster because it doesn’t require a desorption period, as with ethylene oxide. Sterilized devices can therefore reach the market more quickly, providing a competitive advantage for manufacturers.

CSDmed: Championing Supercritical CO₂ Sterilization Standardization

Recognizing the benefits of this method, CSDmed is actively involved in the AFNOR S95R commission to develop a standard dedicated to supercritical CO₂ sterilization. This standard will be the equivalent of ISO 11135 for CO₂, establishing ecological and secure standards for the medical device industry.

As a member of this commission, CSDmed collaborates with experts to promote sustainable sterilization practices that align with the industry’s safety and performance objectives.

Why Choose Supercritical CO₂ Sterilization? A Technology for the Future

Supercritical CO₂ sterilization is not just an eco-friendly alternative; it represents a forward-thinking approach where patient safety goes hand-in-hand with environmental protection. For medical device manufacturers looking to reduce their environmental impact while upholding high safety standards, this technology proves to be a viable option aligned with sustainability values.

Contact us to explore how supercritical CO₂ sterilization can integrate into your manufacturing processes and discover the advantages of this innovative method for a more sustainable production aligned with tomorrow’s standards.